Nasze komory testowe znajdują zastosowanie w wielu branżach przemysłu.

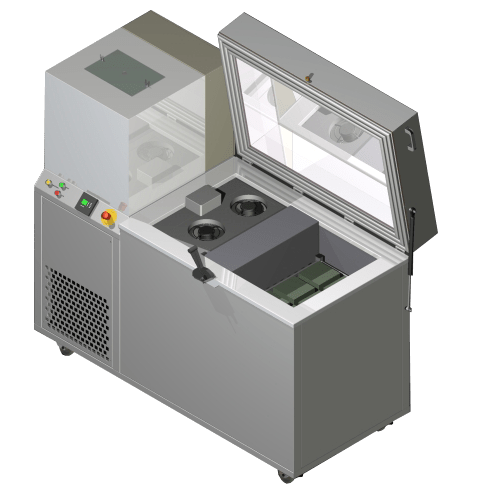

We manufacture devices for testing products in various environmental conditions. Our test chambers are excellent tools for conducting durability tests, assessing functionality, and studying the impact of extreme conditions on products. We offer a wide range of chambers, both laboratory and industrial, that can meet various requirements of our customers.

We design our test chambers with precision and reliability in mind. Equipped with advanced controllers and sensors, they ensure precise control of test conditions. Our chambers are made from high-quality materials that guarantee durability and reliability over the long term. We utilize advanced automation, the latest technologies, and the highest production standards, ensuring that our devices meet our customers’ expectations. We understand that each industry has its unique requirements, which is why we offer individual customization of our chambers.

We not only offer high-quality products but also provide professional advisory services. Our team is here to assist you in selecting the right equipment, offer advice on testing, and provide comprehensive technical support.

Test chambers allow for controlled heating and cooling of products, enabling testing for durability under extreme temperatures. They also create conditions for testing product resistance to high humidity. Vibration chambers assess material resistance to vibrations that may occur during transportation, operation, or other working conditions. Radiation chambers facilitate testing of the impact of sunlight and UV radiation. Contamination chambers allow for the introduction of various chemical substances or gases into the circuit that may affect the tested products.

Test chambers are extremely important in the product development process: they assist in evaluating the durability of the tested material, its functionality, safety, and compliance with industry standards. They allow for thorough product testing in controlled conditions, which can help prevent potential issues and improve the quality and durability of products before they are introduced to the market.

Komór testowych używa się w wielu branżach:

- w przemyśle motoryzacyjnym,

- elektronicznym,

- w aeronautyce,

- farmacji,

- a także na potrzeby badań naukowych.

Accessories and additional features:

- barcode scanner;

- production data recording system with reporting;

- remote access to the device and receiving notifications on your phone;

- audit trail.

01/ TDM Basic

Shelf chamber dryer

| Price: from 76 430 zł netto | Contact us |

General Information:

- test chambers designed for conducting experiments on products and materials;

- ability to build mobile and stationary devices, as well as room adaptation;

- maximum load capacity depends on the type of device.

Heating source:

- electric heater;

- heat pump.

Cooling source:

- refrigeration unit;

- exchanger.

Construction:

- stainless steel AISI 304, AISI 316, galvanized, painted.

Control system:

- 7″-22″ Standard or INOX operator panel, ability to set the process in steps;

- delayed start;

- remote access to the PLC;

- precision of the temperature sensor: ± 0,35 °C;

- production data recording on a USB drive.

Electrical specifications:

- from 1,5 kW (depending on the type of heating element used).

EAPOL

Technology is our passion.

EAPOL Sp. z o.o. od 24 lat dostarcza innowacyjne rozwiązania w zakresie automatyzacji przemysłowej i budowy maszyn. Nasz doświadczony zespół inżynierów realizuje projekty, które zwiększają efektywność i redukują koszty dla klientów z różnych branż.

We have completed 156 projects, offering system design, machine construction, modernization, and service. Our advanced technologies help companies gain a competitive edge and grow in a rapidly changing industrial environment. Customer trust is our greatest motivation.

EAPOL Sp. z o.o. – Innowacyjność, na której możesz polegać.