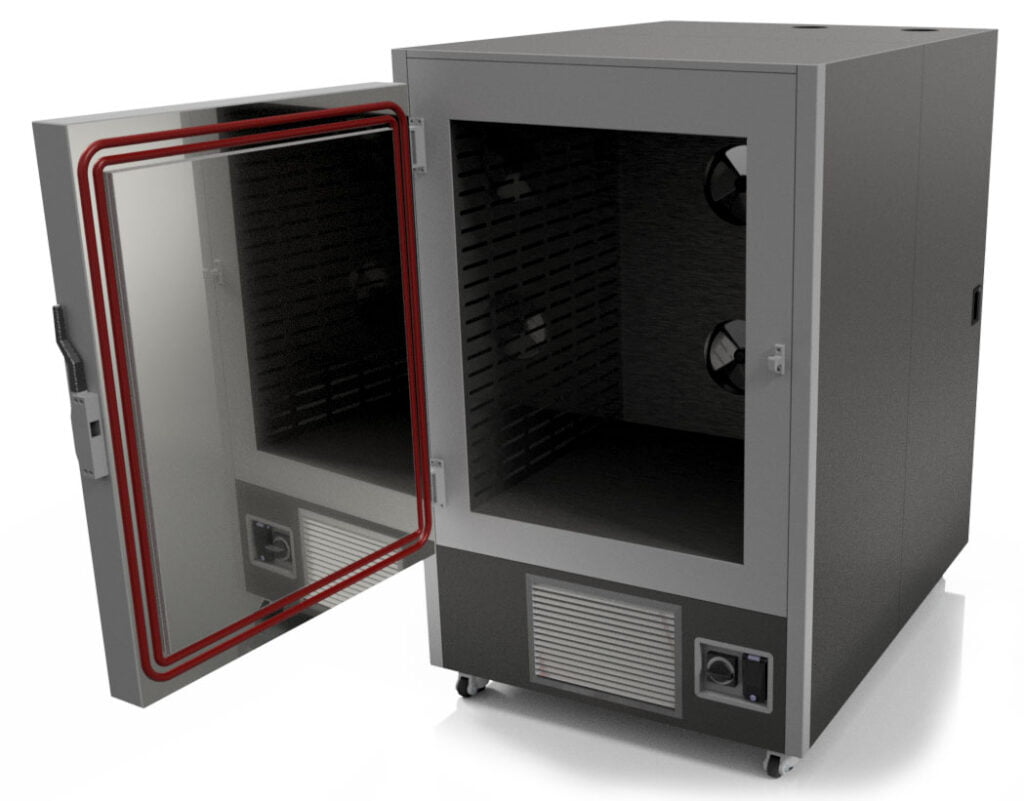

We manufacture high-quality Heating-Up Chambers that find applications in various industrial processes. Our designs prioritize reliability and, above all, meeting the diverse requirements of our customers.

Our devices are equipped with advanced control systems, including Siemens, Mitsubishi Electric, and Weidmuller, enabling precise temperature and heating time control. The program can be divided into multiple steps, where the operating time and temperature are accurately defined. Additionally, it allows for automatic progression to the next step after a specified time or when certain parameters are reached.

We manufacture Heating-Up Chambers using durable materials and components, designed for intensive use in demanding industrial conditions.

Our Heating-Up Chambers are used in various industries, including processing, food, chemical, metallurgical, and glass industries. We can customize the equipment to meet the individual requirements of our clients while ensuring the accuracy and repeatability of the heating process. Our team of engineers and designers will tailor the size, power, control, and other parameters to ensure that the Heating-Up Chambers operates in accordance with the customer’s specifications.

We also design Heating-Up Chambers with energy efficiency in mind, using advanced technologies. This ensures that our equipment minimizes heat loss and allows for energy savings while maintaining high performance.

We also provide professional consulting services for selecting the appropriate Heating-Up Chambers, offer advice on heating processes, and ensure comprehensive technical support.

General Information:

- Heating-Up Chambers designed for conducting production processes;

- Capability to build tray, trolley, and belt Heating-Up Chambers

- the maximum load depends on the type of Heating-Up Chambers construction;

- compliance with GMP and FDA requirements.

Heating source:

- electric power;

- gas heater.

Manufacture:

- stainless steel AISI 304, AISI 316, galvanized, painted.

Control system:

- 7″-22″ Standard or INOX operator panel, ability to set the process in steps;

- delayed start;

- automatic chamber cooling after completed the process;

- remote access to the PLC;

- precision of the temperature sensor: ± 0,35 °C;

- production data recording on a USB drive.

Electrical specifications:

- from 1,5 kW (depending on the type of heating element used).

Accessories and additional features:

- barcode scanner;

- production data recording system with reporting;

- remote access to the device and receiving notifications on your phone;

- interior chamber lighting;

- audit trail;

- predictive maintenance package.