Efektywne suszarnie bębnowe konwekcyjne i promiennikowe dopasowane do Twojej produkcji

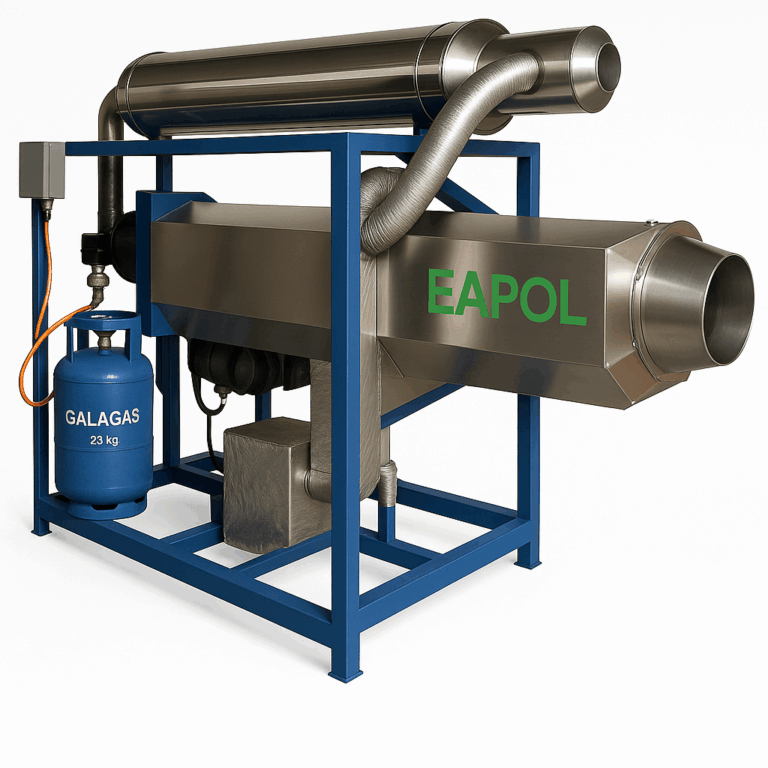

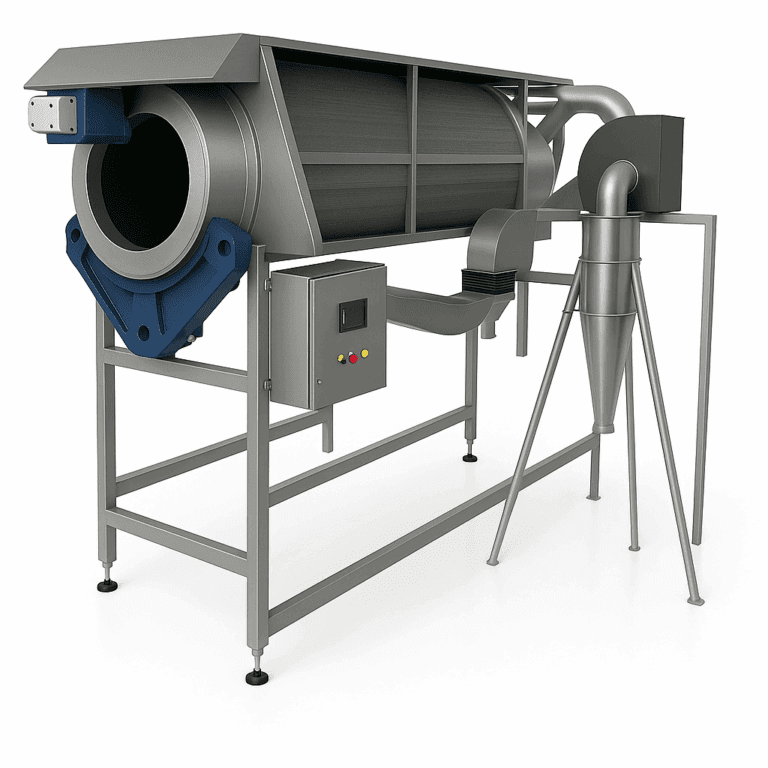

Dryers bębnowe sprawdzają się w wielu gałęziach przemysłu spożywczego, farmacji i chemii, aż po produkcję pasz. Oferujemy urządzenia o wydajności od 30 kg/h do 1 000 kg/h i średnicach bębnów od 300 do 2 800 mm, dostępne zarówno w wersji konwekcyjnej, jak i promiennikowej, z zasilaniem gazowym, olejowym lub elektrycznym.

Każdy model wyposażony jest w zaawansowany układ sterowania, który precyzyjnie reguluje prędkość obrotową bębna oraz temperaturę procesu, co gwarantuje powtarzalność i stabilną jakość suszenia nawet dla najbardziej wymagających materiałów – od proszków spożywczych czy prażonej kawy, przez granulaty i sorbenty, po specjalistyczne produkty odzwierzęce wykorzystywane w przemyśle kolagenowym.

Dzięki efektywności energetycznej na poziomie około 2 kW zużycia na odparowanie 1 kg wody w ciągu godziny nasze suszarnie minimalizują koszty eksploatacji i serwisu, a solidne komponenty zapewniają długą żywotność całego układu. Na życzenie wykonujemy testy suszenia na dostarczonym surowcu, by jeszcze przed zakupem potwierdzić optymalne parametry procesu.

Ponadto oferujemy indywidualne dostosowanie wymiarów i wyposażenia urządzenia oraz kompleksowe wsparcie – od doradztwa technicznego, przez projekt, aż po uruchomienie i szkolenie personelu. Skontaktuj się z nami, aby dobrać suszarnię bębnową promiennikową lub konwekcyjną idealnie dopasowaną do Twoich potrzeb.

Accessories and additional features:

- czytnik kodów kreskowych

- system rejestracji danych produkcyjnych wraz z raportem

- zdalny dostęp do urządzenia i otrzymywanie powiadomień na telefon

- okno rewizyjne w drzwiach suszarni wraz z oświetleniem wnętrza

- ścieżka audytu (audit trail)

- bezkontaktowy pomiar temperatury

- pakiet predykcyjnego utrzymania ruchu

Kluczowe zastosowania suszarni:

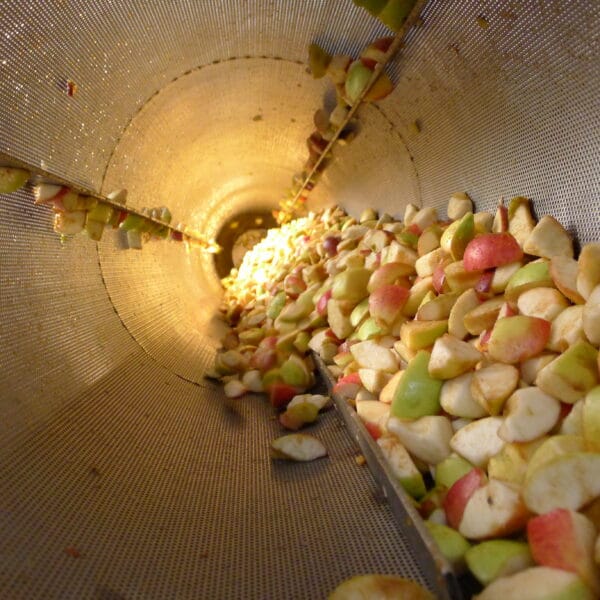

- Suszenie produktów po ekstruzji (snacki, pasze)

- Suszenie proszków spożywczych (mleko w proszku, przyprawy)

- Prażenie kawy i orzechów z precyzyjną kontrolą aromatu

- Suszenie ziaren (kukurydza, soja, słonecznik)

- Specjalistyczne suszenie produktów odzwierzęcych (np. paznokcie wołowe do kolagenu)

- Suszenie granulatów i sorbentów (chemia, nawozy)

- Ekonomiczne osuszanie młóta browarnianego, wytłoków owocowych i odpadów do produkcji pasz

Drum dryers

| Price: zapytaj nas | Contact us |

General Information:

- suszarnia bębnowa przeznaczona do suszenia produktów spożywczych, chemicznych i farmaceutycznych, spełniająca normy GMP i FDA

- wydajność od 30 kg/h do 1 000 kg/h, w zależności od modelu

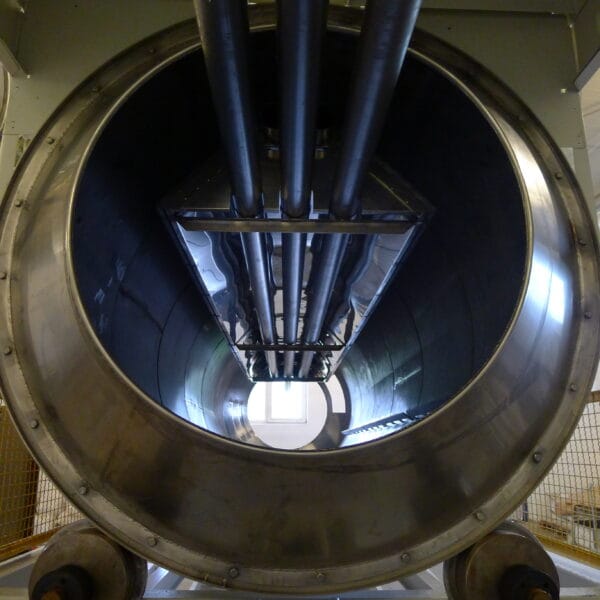

- średnica bębna od 300 mm do 2 800 mm, długość dostosowana do wymagań klienta

- możliwość przeprowadzenia testów suszenia na dostarczonym surowcu przed zakupem

Heating source:

- gaz ziemny

- propan-butan

- olej opałowy

- w pełni elektryczne

- automatyczna modulacja mocy palnika lub grzałek dla utrzymania stabilnej temperatury

Construction:

- stal nierdzewna AISI 304 lub AISI 316 (opcjonalnie malowana proszkowo lub ocynkowana)

- solidna, modularna konstrukcja ułatwiająca transport i montaż

- izolacja termiczna minimalizująca straty ciepła

Control system:

- 7″-22″ Standard or INOX operator panel, ability to set the process in steps;

- delayed start;

- remote access to the PLC;

- precision of the temperature sensor: ±0,35 °C;

- production data recording on a USB drive.

Dane elektryczne i energooszczędność:

- minimalna moc grzewcza od 5 kW (w zależności od wydajności modelu)

- zużycie energii na poziomie około 2 kW do odparowania 1 kg wody w ciągu godziny

Suszarnie bębnowe — Najczęściej zadawane pytania (FAQ)

Orientacyjne zużycie energii w naszych suszarniach bębnowych wynosi około 2 kW na odparowanie 1 kilograma wody w ciągu godziny. Jest to wartość szacunkowa, a rzeczywiste zużycie zależy od wielu czynników, takich jak rodzaj i wilgotność początkowa suszonego materiału (np. granulatu, proszku spożywczego, kawy), wymagana wilgotność końcowa oraz konkretne parametry ustawione dla danego procesu suszenia. Kładziemy duży nacisk na projektowanie energooszczędnych rozwiązań.

Cena każdej suszarni bębnowej jest kalkulowana indywidualnie. Kluczowe czynniki wpływające na koszt to: wymagana wydajność (oferujemy modele od 30 kg/h do 1000 kg/h), gabaryty urządzenia (średnica bębna od 300 do 2800 mm, długość), typ zastosowanego zasilania (gaz, olej opałowy, energia elektryczna), materiały konstrukcyjne (np. stal nierdzewna dla przemysłu spożywczego/farmaceutycznego) oraz poziom automatyzacji i systemów kontroli. Aby uzyskać dokładną ofertę cenową dopasowaną do Państwa specyficznych potrzeb, zapraszamy do bezpośredniego kontaktu.

Produkujemy suszarnie bębnowe o zróżnicowanych wymiarach, dostosowanych do potrzeb technologicznych i przestrzennych naszych klientów. Średnica bębna może wynosić od 300 mm do 2800 mm. Długość bębna oraz całkowite gabaryty maszyny są projektowane indywidualnie, uwzględniając specyfikę suszonego produktu, wymaganą wydajność oraz warunki instalacji w Państwa zakładzie.

Standardowy czas realizacji zamówienia na suszarnię bębnową jest ustalany indywidualnie dla każdego projektu. Zależy on od stopnia skomplikowania urządzenia, jego wielkości, wymaganej specyfikacji technicznej oraz naszego aktualnego harmonogramu produkcyjnego. Po zebraniu wszystkich niezbędnych informacji i uzgodnieniu szczegółów technicznych, jesteśmy w stanie podać precyzyjny termin dostawy i montażu.

EAPOL

Technology is our passion.

EAPOL Sp. z o.o. od 24 lat dostarcza innowacyjne rozwiązania w zakresie automatyzacji przemysłowej i budowy maszyn. Nasz doświadczony zespół inżynierów realizuje projekty, które zwiększają efektywność i redukują koszty dla klientów z różnych branż.

We have completed 156 projects, offering system design, machine construction, modernization, and service. Our advanced technologies help companies gain a competitive edge and grow in a rapidly changing industrial environment. Customer trust is our greatest motivation.

EAPOL Sp. z o.o. – Innowacyjność, na której możesz polegać.